Snowwhite2 paper: Innovating Steel – Filters & Refractories

Welcome back to our exploration of cutting-edge research made possible, in part, by the precision of the Sharebot Snowwhite SLS 3D printing technology. Today, we’re featuring the scientific paper “Functionalized Feeders, Hollowware, Spider Bricks and Starter Casting Tubes for Increasing the Purity in Steel Casting Processes“. To begin, we’ll provide a straightforward explanation of what the study investigated and the main results it uncovered. Following this accessible overview, we’ll share the original abstract and relevant citations for a more in-depth look.

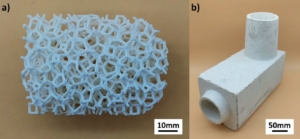

a) Template printed using Snowwhite – b) Runner end piece for industrial casting

Understanding the study and its main result

This paper is about improving the purity of steel during a specific casting process called “ingot casting by bottom teeming.” This method is often used for high-quality, specialized steels.

The researchers found a promising way to make the steel cleaner: by using filters. They made special foam-like filters using a 3D printing technique called selective laser sintering (SLS), and they specifically used our Snowwhite printer for this. These printed foam structures were then turned into strong filters using other techniques.

They also looked at improving the containers and tubes (called “hollowware refractories”) that hold and guide the molten steel. They made these components “reactive” by adding special coatings, which helps remove existing impurities and stops new ones from forming.

The big idea is to use both the Sharebot Snowwhite-produced “active” filters and the “reactive” hollowware components together. This combination creates a powerful filtration system that uses the best parts of both methods to clean the steel.

They tested these new ideas in real industrial settings with a company called Deutsche Edelstahlwerke Specialty Steels Europe GmbH (DEW). After the tests, they examined the materials and steel samples to see how well the new methods worked compared to the old ones.

Main result

The key discovery here is the development of a combined filtration system that significantly improves the purity of specialty and alloy steels during ingot casting. By simultaneously using 3D-printed “active” filters and specially coated “reactive” refractory components, they found a more effective way to remove impurities from molten steel. This leads to higher quality steel products.

Functionalized Feeders, Hollowware, Spider Bricks and Starter Casting Tubes for Increasing the Purity in Steel Casting Processes

Tony Wetzig, Matthias Schwarz, Leandro Schöttler, Patrick Gehre & Christos G. Aneziris

Ref.: https://link.springer.com/chapter/10.1007/978-3-031-40930-1_32

Abstract

Although continuous casting became the state of the art for the casting of ordinary steel grades, ingot casting by bottom teeming still has relevance in the steelmaking industry, especially for the manufacturing of specialty and alloy steels. As for every casting process, the ever-increasing quality requirements by customers lead to increased demand for new technologies to increase the purity of the cast steel melt regarding its inclusion content. Due to the special design of the bottom-teeming ingot casting facility and the discontinuous operation as batch process, the application of filters is a promising approach. Tailored foam geometries were prepared based on additive manufacturing via selective laser sintering (SLS) and transformed into filters via modified replication techniques and flame spraying. Additionally to filter application, the functionalization and quality improvement of applied hollowware refractories has high potential to remove existing inclusions from the steel melt and avoid the formation of new inclusions during casting. The investigated hollowware components were manufactured by pressure slip casting on the basis of coarse-grained alumina compositions and subsequent functionalization by spray coating based on carbon-bonded alumina slurries. Simultaneous application of functionalized, “reactive” refractory components and flame-sprayed, “active” filters enables a combined filtration system which unites the advantages of the distinct filtration mechanisms. In the continuous casting of specialty steels, the conditions are more severe resulting in additional challenges regarding the application of filters. An approach investigated in this subproject is the use of extruded filter starter casting tubes above the tundish outlet. To achieve this, extrusion mixes based on cellulose derivatives and materials of the system Al2O3-ZrO2-C (AZC) were investigated for their suitability. The new concepts were tested in industrial casting trials in cooperation with the company Deutsche Edelstahlwerke Specialty Steels Europe GmbH (DEW). Post-mortem, the former melt-refractory interface of the applied components was investigated and steel samples from the ladle, the gating system and the ingot were analyzed in comparison to untreated samples.