Snowwhite2 paper: Recovery of rare elements from mining wastewater

Welcome back to our series highlighting the exciting ways the Snowwhite SLS 3D printing technology is contributing to scientific discovery. Today, we’re diving into the research presented in the paper “Recovery of rare earth elements from mining wastewater with aminomethylphosphonic acid functionalized 3D-printed filters“. We’ll start by explaining the core of this study and its main findings in simple terms, making it easy to understand. After that, we’ll take a look at the original abstract and any relevant references for those who want to delve deeper into the specifics of the research.

Understanding the study and its main result

This scientific paper talks about a new way to get valuable metals called Yttrium (Y), Neodymium (Nd), and Dysprosium (Dy) from waste left over from mining. This waste also has other metals like Aluminum (Al), Potassium (K), Calcium (Ca), Scandium (Sc), Iron (Fe), Cobalt (Co), Copper (Cu), Zinc (Zn), and Uranium (U).

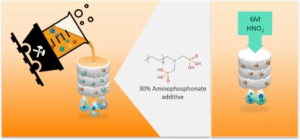

The scientists made special filters using a our Snowwhite2 and Nylon-12. They added another chemical, α-aminomethylphosphonic acid, to these filters to help grab the metals. They chose Nylon-12 because it doesn’t react with the metals they were studying. They used powerful microscopes and X-rays to see the tiny structure of the filters, like how many holes they had and how the special chemical was spread inside. They also used another technique called FTIR to see how the filters changed after they were made and after they soaked up the metals. The scientists tested how well the filters could grab the metals at different levels of acidity (pH). They found that Scandium (Sc) was grabbed the most, followed by Iron (Fe) and Uranium (U), and then Y, Nd, and Dy. Aluminum, Copper, Zinc, Potassium, Calcium, and Cobalt were grabbed the least. They then tried to take the valuable metals back out of the filters using a strong acid. They found that they could get most of the Y, Nd, and Dy back out, but Scandium, Iron, and Uranium stayed stuck in the filters.

Main result

The main discovery is that these specially designed 3D-printed filters can effectively separate and recover the valuable rare earth elements Yttrium (Y), Neodymium (Nd), and Dysprosium (Dy) from complex mining waste, while leaving behind unwanted metals like Scandium, Iron, and Uranium. This method could be useful for cleaning up mining waste and getting valuable resources at the same time.

Recovery of rare earth elements from mining wastewater with aminomethylphosphonic acid functionalized 3D-printed filters

Emilia J. Virtanen (a) (c), Esa Kukkonen (a) (c), Janne Yliharju (b) (c) (d) , Minnea Tuomisto (e), Janne Frimodig (a), Kimmo Kinnunen (b) (c), Elmeri Lahtinen (a), Mikko M. Hänninen (a), Ari Väisänen (a), Matti Haukka (a), Jani O. Moilanen (a) (c)

a) Department of Chemistry, University of Jyväskylä, P.O. Box 35, FI-40014 Jyväskylä, Finland

b) Department of Physics, University of Jyväskylä, P.O. Box 35, FI-40014 Jyväskylä, Finland

c) Nanoscience Center, University of Jyväskylä, P.O. Box 35, FI-40014 Jyväskylä, Finland

d) School of Resource Wisdom, University of Jyväskylä, P.O. Box 35, FI-40014 Jyväskylä, Finland

e) Department of Chemistry, University of Turku, FI-20014 Turku, Finland

Ref: https://www.sciencedirect.com/science/article/pii/S1383586624023384#f0045

Abstract

Herein we report the use of nylon-12-based 3D-printed filters incorporating α-aminomethylphosphonic acid as an active additive for the recovery of Y, Nd, and Dy from the mining waste solution containing Al, K, Ca, Sc, Fe, Co, Cu, Zn, Y, Nd, Dy, and U. Nylon-12 was chosen for the polymer matrix of the filter due to its inactivity towards the studied metals. The micrometer-level structure of the filters was studied with a scanning helium ion microscope and X-ray tomography to reveal the porosity, pore size, and active additive distribution in the filters. Furthermore, FTIR spectroscopy was used to analyze the compositional changes in the 3D-printed filters after the printing and adsorption processes. Adsorption of the metals was studied at a pH range of 1–4, and the following adsorption trend Sc > Fe > U > Y, Nd, Dy > Al, Cu, Zn > K, Ca, Co was observed in each of the studied pH values. The sequential recovery process for metals was studied at pH 2, and desorption of the metals from the filters was performed with 6 M HNO3. 100 % adsorption of REEs, Fe, and U was achieved during the recovery process, and on average, over 88 % of the adsorbed Y, Nd, and Dy were desorbed from the filters. In contrast to Y, Nd, and Dy, the desorption of Sc, Fe, and U was minimal (Fe and U) or negligible (Sc) with 6 M HNO3 due to their strong coordination to the active additive. Maximum adsorption capacities for Y, Nd, Dy, and U were determined by using linear Langmuir adsorption isotherm. The best maximum adsorption capacity was determined for Sc, Qmax = 0.51 mmol/g followed by U, Nd, Dy, and Y with capacities of 0.47, 0.24, 0.23, and 0.17 mmol/g, respectively. Overall, this study achieved a complete removal of Sc, Fe, and U from the simulated mining waste solution leaving a final eluate that mainly contained Y (320 μg), Nd (350 μg), Dy (330 μg), and Al (710 μg) demonstrating the applicability of the 3D-printed filters in the recovery of Y, Nd, and Dy from the multimetal solution.