GALAXY

DLP Technology – resin

Professional DLP 3D printer for advanced solutions

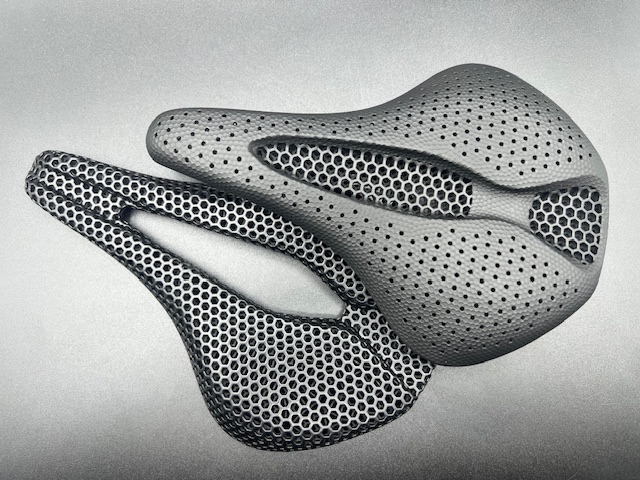

When the market demands durable, elastic, and functional products, Sharebot GALAXY’s DLP technology becomes the ideal tool for transforming advanced resins into consumer products ready for real-world use. Thanks to a high-resolution, high-power DLP projector, GALAXY can precisely polymerize two-component polyurethane resins, materials that combine high elasticity, mechanical strength, and long-term stability—essential characteristics for products subject to wear, bending, or repeated stress.

This capability makes it perfect for the direct production of parts in the consumer goods sector: ergonomic razors, anatomical cushions, handles, sports and leisure accessories, components for wearable devices, and much more. These are no longer simple prototypes, but finished, high-performance, and marketable objects, printed without molds, without tools, and with development times reduced by 70% compared to traditional methods.

Why does GALAXY stand out in the DLP landscape?

R&D print volume: 192 x 108 x 500 mm ideal for prototypes

XY resolution of 100 µm: sharp details, smooth surfaces, and precise tolerances

Print speed up to 10 cm/hour: high productivity even for small series

Compatibility with two-component polyurethane resins: elastomeric materials with mechanical properties comparable to thermoplastic rubber (TPU), but with greater durability and elastic recovery

Full connectivity (Wi-Fi, Ethernet, USB) and remote management for integration into professional work environments