Snowwhite2: Work with Low-Melt Thermoplastic Powders

Flexibility and Innovation in SLS Printing

The Sharebot SnowWhite² system is designed to process a wide range of thermoplastic powders, from high-performance materials (with build-chamber temperatures up to 190 °C in the standard version and 350 °C in the HT version) to low-melt polymers with melting points below 100 °C.

When working with low-melt powders, it’s essential to adjust the thermal management strategy inside the build chamber. The default heating parameters are optimized for materials with much higher melting points; applying them directly could result in overly aggressive heating and potential material degradation.

Lamp-Based Heating Control

The SnowWhite² uses halogen lamps to heat the powder bed. The amount of energy delivered to the powder depends on the minimum and maximum lamp-intensity settings.

Low-melt materials generally require a gentler and more gradual warm-up, often in a single heating step. To achieve this, users must fine-tune the lamp-power range. This is done by enabling the “Lamps Control” plugin, which unlocks the “Lamps Min” and “Lamps Max” parameters. Adjusting these values allows precise control over the lower and upper limits of lamp intensity, ensuring a smoother heating curve.

Thermal Equilibrium

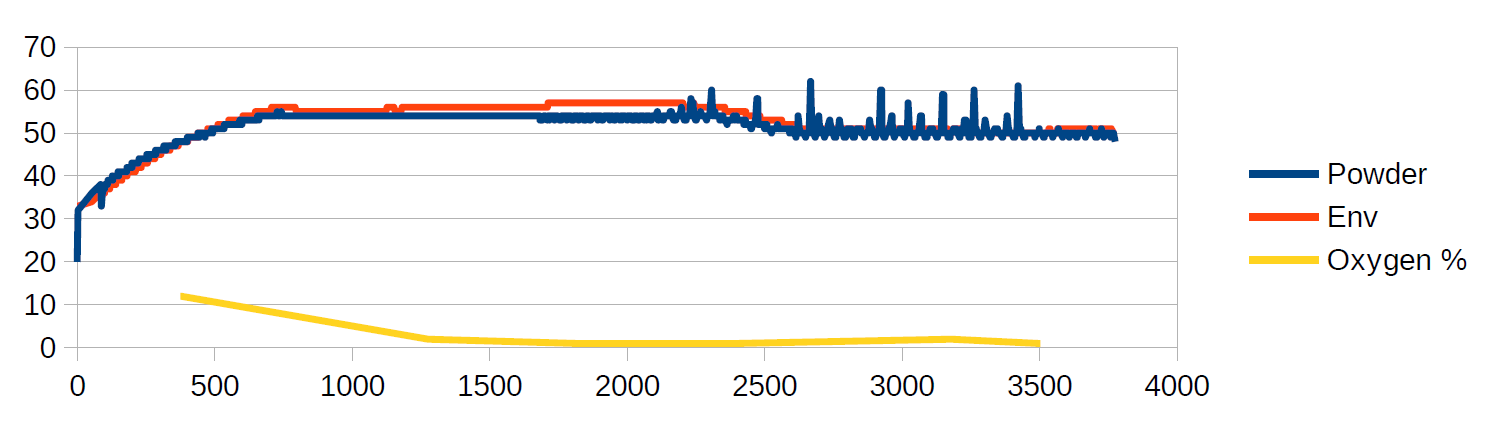

Once the desired chamber temperature is reached, the system should remain at thermal equilibrium for at least 15 minutes. This stabilization phase ensures that all machine components and the powder achieve uniform temperature conditions before printing begins.

Application Example: Polycaprolactone (PCL)

-

Printing chamber temperature: 55–60 °C

-

Material behavior: PCL is highly sensitive to temperature fluctuations and has a very narrow process window. To achieve a smooth and controlled warm-up, we adjusted the lamp-power settings from the default:

Original settings:

-

Minimum: 20%

-

Maximum: 100%

Custom settings for PCL:

-

Minimum: 0%

-

Maximum: 20%

These adjustments significantly reduce thermal stress on the powder and enable consistent, high-quality sintering of low-melt materials.

Temperature graph/plot during the build process.