Optimizing Process Parameters for metal alloy

TECHNICAL WHITE PAPER

Optimizing Process Parameters for Metal Alloy

3D Printing Advanced Testing Tools Developed by Sharebot

1. Introduction

In the field of metal additive manufacturing (AM), the optimization phase of metal powders and process parameters is critical to achieving components with optimal mechanical and microstructural properties.

Powder Bed Fusion (PBF-LB/M) technologies—where a laser beam selectively melts thin layers of metal powder—require precise control over the energy parameters governing melting and subsequent solidification.

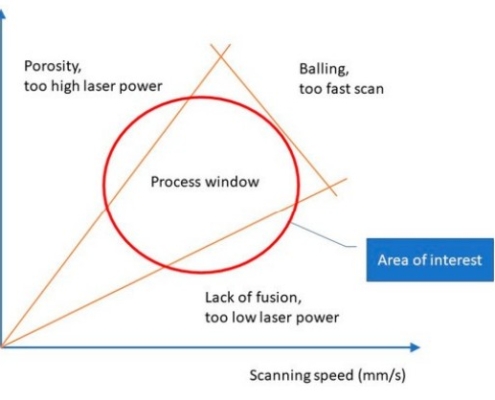

Among the most influential parameters are laser power (P), scan speed (v), and focal plane position (z₀).

The combination of these factors determines the amount of energy locally delivered to the powder bed, directly affecting part density, melt pool morphology, and residual porosity.

2. Process Fundamentals

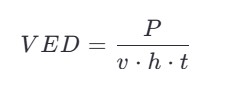

The efficiency of the PBF process is commonly described using Volumetric Energy Density (VED), calculated as:

where:

P = laser power (W)

v = scan speed (mm/s)

h = hatch distance (mm)

t = layer thickness (mm)

VED represents the energy input per unit volume and helps predict the degree of material melting.

Too low VED leads to lack-of-fusion defects and high porosity, while excessive VED can cause melt instability, localized evaporation, or residual stresses.

3. Sharebot’s Automated Parametric Testing Function

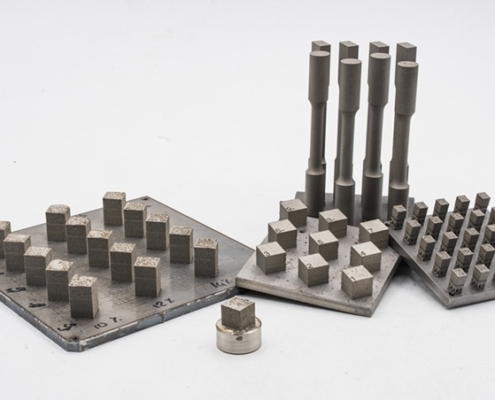

To streamline powder qualification and process optimization, Sharebot has developed an integrated automated parametric testing function within its machine software.

This tool generates a matrix of cubic test specimens, systematically varying laser power and scan speed along two axes.

In a single print session, up to 25 test cubes (e.g., a 5×5 array) can be produced—each with a unique combination of process parameters.

The ordered layout enables immediate visual and analytical comparison, simplifying the identification of the optimal processing window and drastically reducing calibration time.

4. Density Characterization

The printed specimens can undergo hydrostatic density measurement based on Archimedes’ principle, a method that determines the actual density of the material.

By comparing the measured density with the theoretical density of the alloy, researchers can estimate residual porosity and assess fusion quality.

Further metallographic analyses (optical microscopy, SEM) and mechanical tests (microhardness, tensile strength) allow correlation between microstructural features and the applied process conditions.

5. Low-Volume Powder Printing

To support R&D on advanced or experimentally formulated alloys, Sharebot has engineered a low-volume powder dispensing system.

This innovative solution enables the production of single 1 cm³ test cubes using just a few grams of powder, making it ideal for evaluating small lab-scale powder batches.

This capability significantly reduces development costs and accelerates preliminary validation of novel high-performance alloys for aerospace, medical, and advanced research applications.

With our metalONE is possible to print a single cube with few powder’s grams to start test !

6. Conclusions

Sharebot’s approach provides an efficient and scalable method for calibrating process parameters in metal 3D printing.

By integrating automated parametric testing and low-powder-volume printing, the company reduces experimentation time, optimizes material usage, and fosters the development of innovative materials.

These tools empower researchers to efficiently explore the relationship between process parameters, microstructure, and mechanical properties, opening new pathways for high-performance alloy design and applied research in additive manufacturing.

Author

R&D Department – Sharebot Srl

Specialists in additive manufacturing technologies and advanced materials development

metalone@sharebot.it | www.sharebot.it