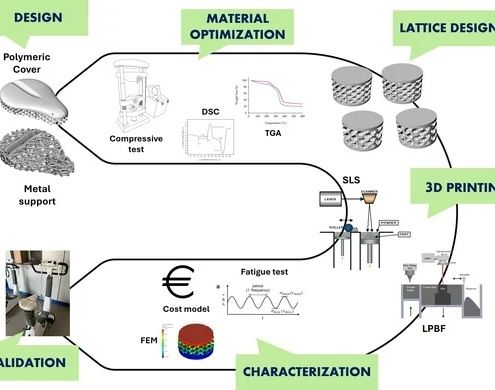

Welcome back to our exploration of cutting-edge research made possible, in part, by the precision and flexibility of the Sharebot Snowwhite SLS 3D printing technology. Today, we are featuring the study ‘Design and fabrication of a modular ergonomic saddle for rehabilitation cycling through a combined additive manufacturing approach.‘ This research highlights how the Snowwhite’s open-system capabilities allow scientists to move beyond standard manufacturing, enabling the development of complex, patient-specific lattice structures in TPU. To begin, we will provide a straightforward explanation of how the researchers optimized these materials and the main results they uncovered. Following this accessible overview, we will share the original abstract and relevant citations for a more in-depth look at the data.

Research Summary: A Modular Saddle for Rehabilitation

This study focuses on creating a high-tech, customizable bike saddle specifically designed for patients in physical rehabilitation. Traditional saddles can be uncomfortable or lack the specific support needed for medical recovery, so the researchers turned to 3D printing to create a “hybrid” solution.

The Design Approach

The researchers used a two-part modular design to balance strength and comfort:

-

The Base: Made of stainless steel using Laser Powder Bed Fusion (LPBF) to provide a rigid, reusable foundation.

-

The Cover: This is where the SLS technology shines. The researchers needed a material that was flexible yet durable, eventually choosing TPU (Thermoplastic Polyurethane) over Polypropylene (PP).

Why SLS was Critical for Research

The study used SLS to create complex “Gyroid Lattice” structures. These are porous, sponge-like internal patterns that allow the saddle to be soft in some areas and firm in others. By using a research-grade SLS printer, they were able to test different cell sizes and wall thicknesses to find the “sweet spot” for patient comfort.

The Testing Process

-

Material Screening: They used thermal analysis to prove TPU was easier to process and better at absorbing energy.

-

Durability: They “tortured” the printed TPU covers with 10,000 compression cycles to ensure they wouldn’t lose their shape during long-term use.

-

Computer Modeling: They used Finite Element Method (FEM) simulations to predict how the saddle would deform under a rider’s weight.

The Discovery: What did they find?

The researchers successfully proved that modular additive manufacturing is both technically and economically viable for medical equipment.

The specific “Breakthrough” findings were:

-

The Optimal Geometry: They identified that a gyroid lattice with an 8 mm cell size and 0.3 mm wall thickness provided the perfect balance—it was flexible enough for comfort but stable enough not to break or permanently deform.

-

Economic Sustainability: Because the expensive metal base is standardized and reusable, only the 3D-printed TPU cover needs to be customized for each patient. This significantly lowers the cost of personalized medical gear.

-

Functional Success: The final prototype was not just a lab experiment; it was successfully mounted and tested on a real cycle ergometer, proving it works in the real world.